CHECK VALVE - POPPET

65

Directional Valves

1900K SERIES - HIGH PRESSURE

CHECK VALVE - POPPET

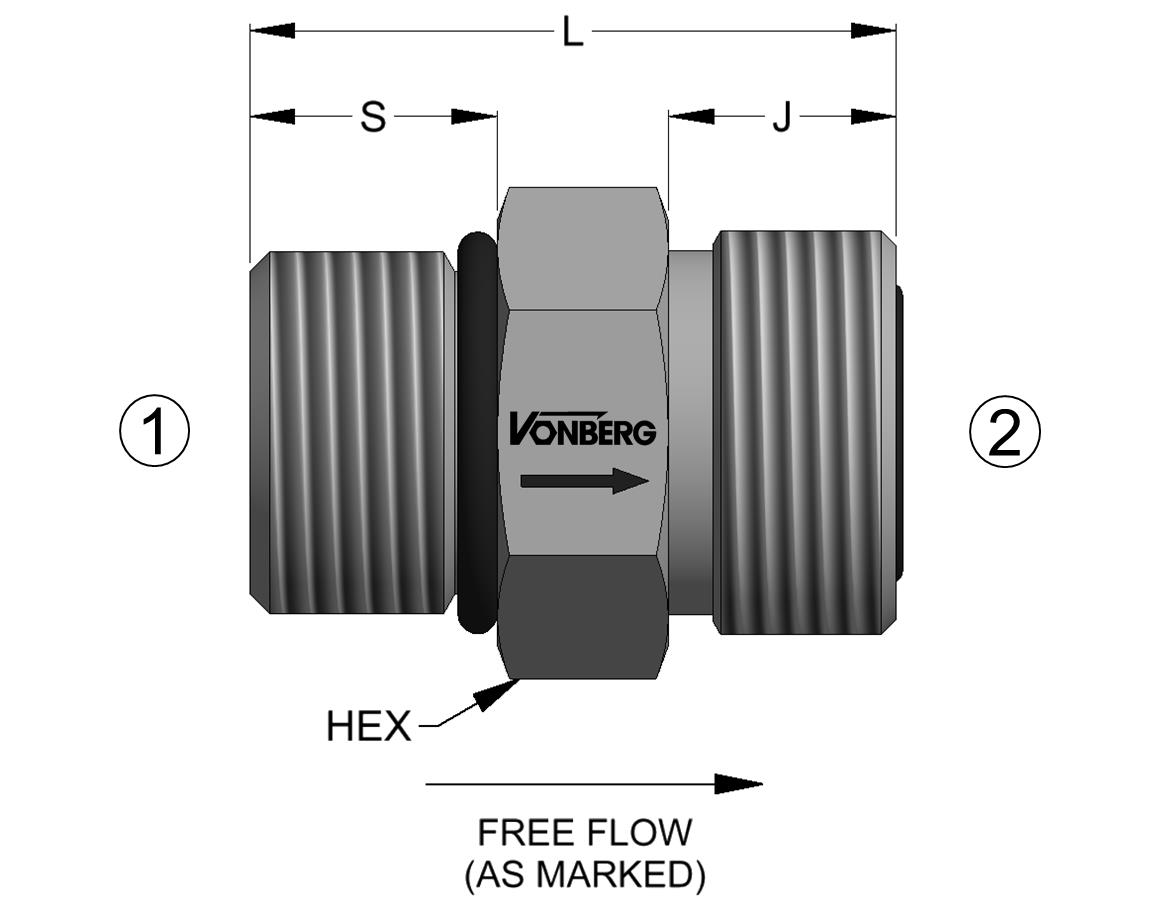

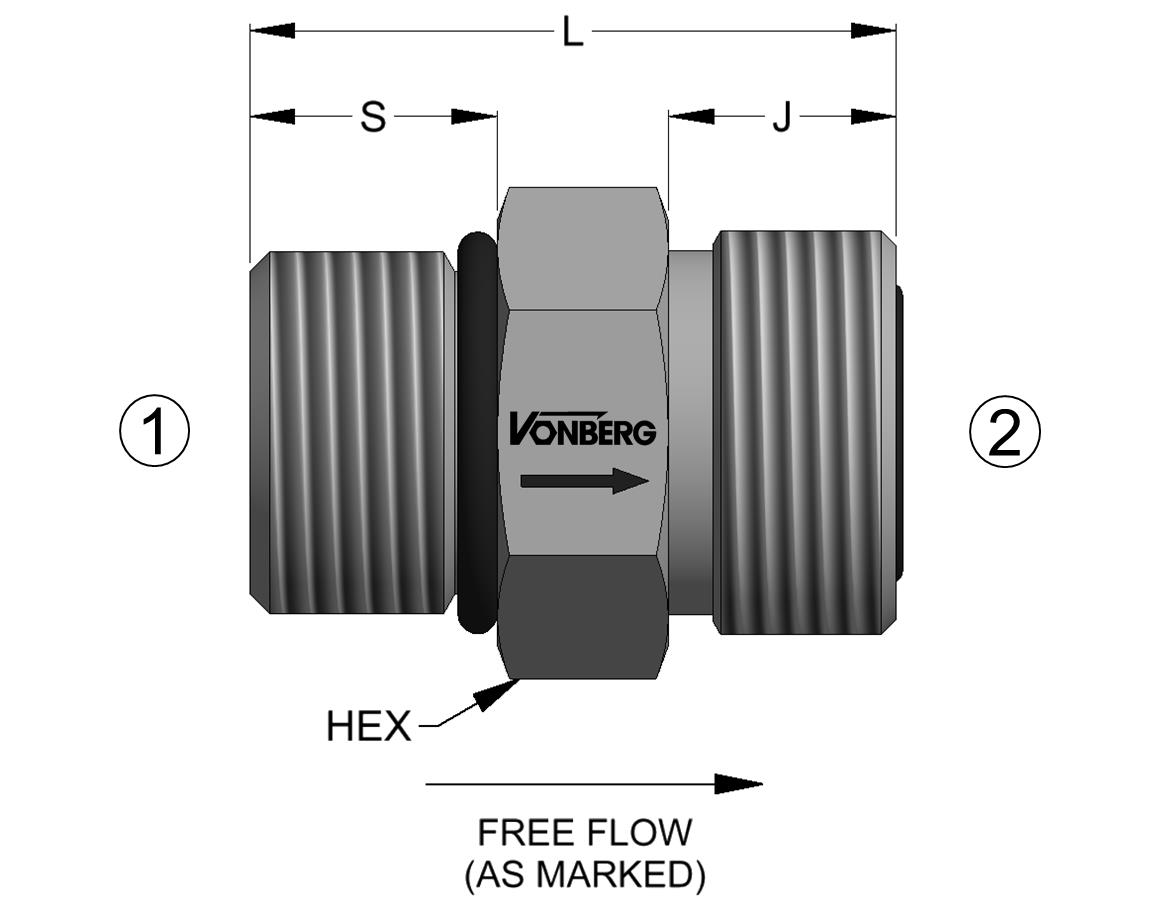

INLINE •

MALE SAE TO MALE ORS

Description

AN IN-LINE STYLE

CHECK VALVE INTENDED FOR

BLOCKING FLUID FLOW.

Product Rendering

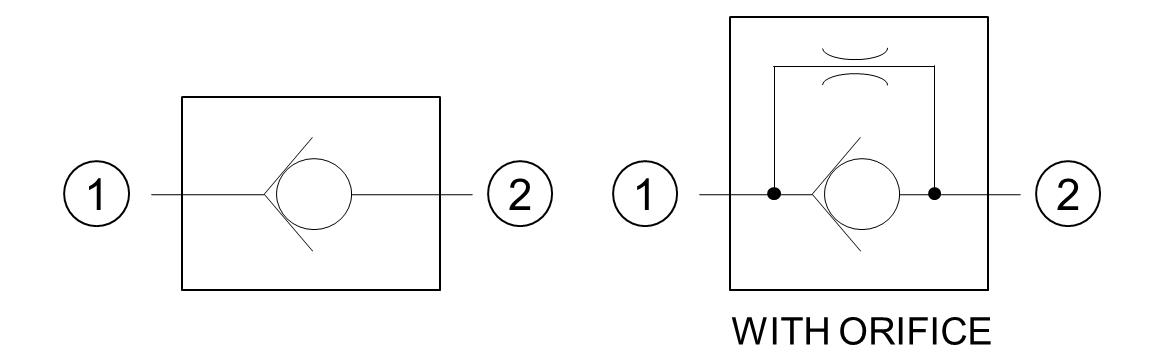

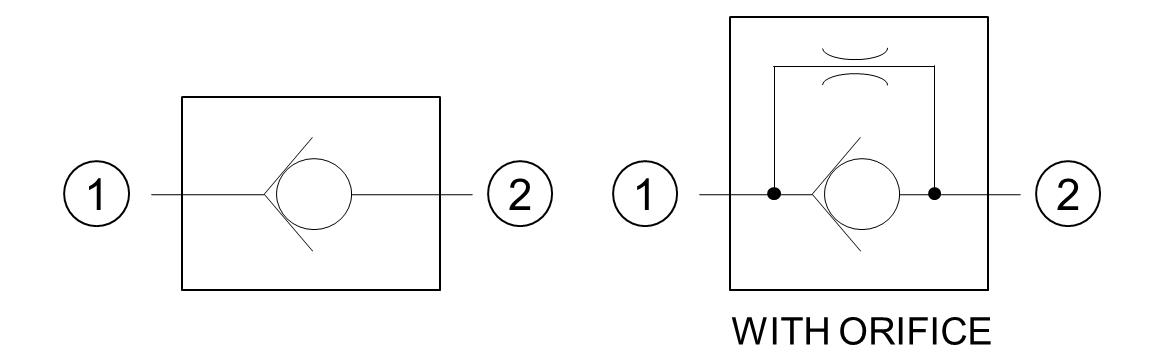

Schematic

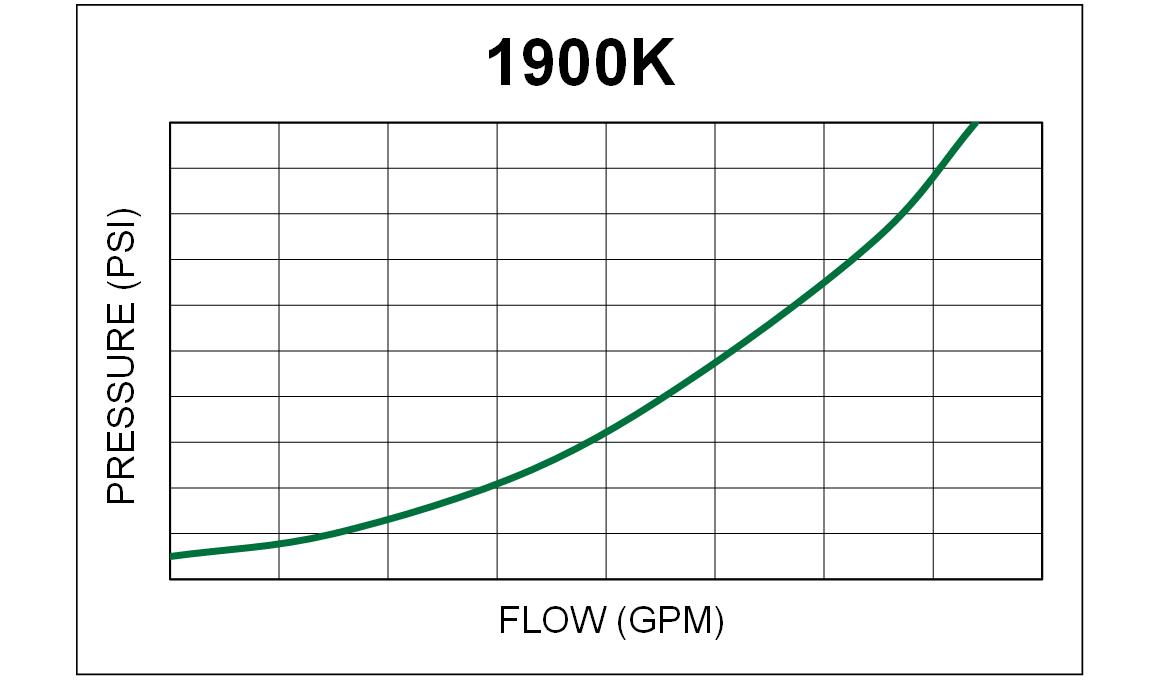

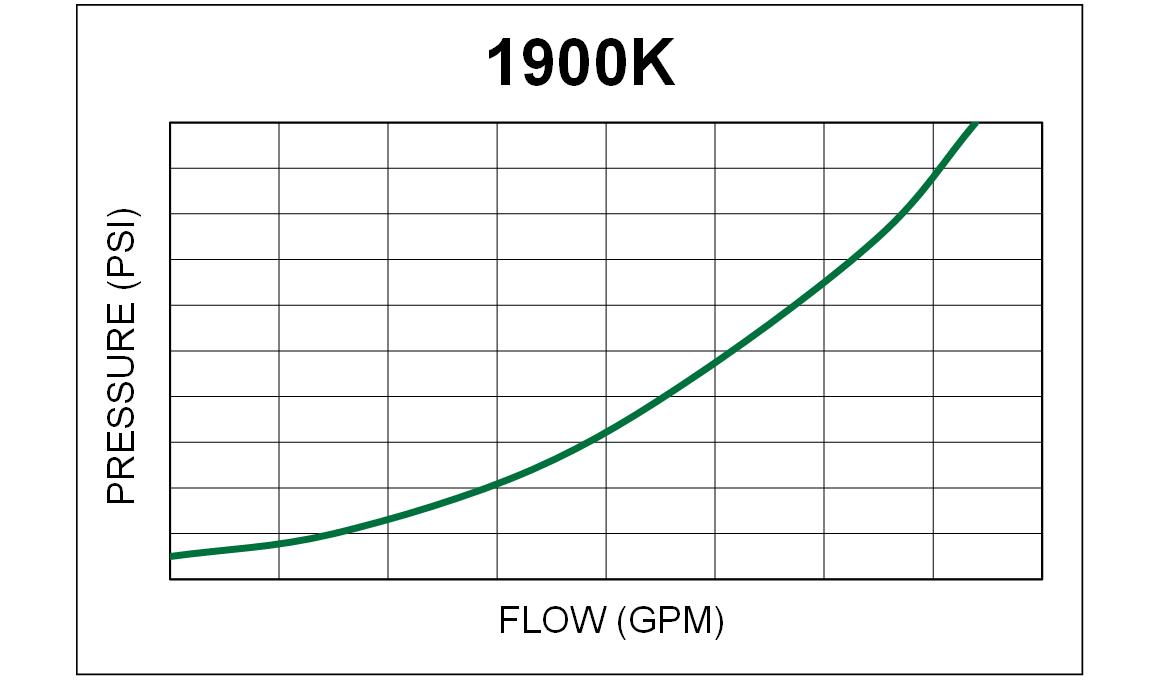

Typical Performance

Operation

- FLOW FROM (1) TO (2) IS ALLOWED WITH A STANDARD CRACK PRESSURE OF 3-5 PSI.

- FLOW FROM (2) TO (1) IS BLOCKED WITH A SPRING BIAS TO ASSIST IN STATIC AND LOW LOAD CONDITIONS.

Features

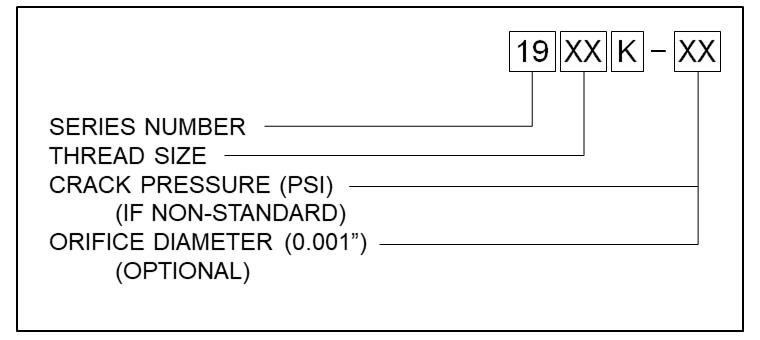

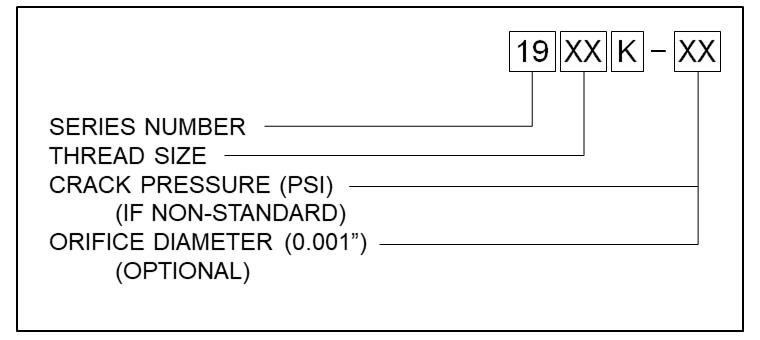

- SPECIAL CRACK PRESSURES AVAILABLE UPON REQUEST.

- LOW INTERNAL LEAKAGE, 5 DPM.

- STEEL BODY AND POPPET.

Specifications

| OPERATING PRESSURE |

5000 PSI |

| STANDARD CRACK PRESSURE |

3-5 PSI |

| TEMPERATURE RANGE |

250° F TO -40° F |

Ordering Information

| 1904K | -04 SAE - 7/16-20 | -04 ORS - 9/16-18 | 2 GPM | 1.07 | 0.38 | 0.43 | 0.625 |

1906K | -06 SAE - 9/16-18 | -06 ORS - 11/16-16 | 4 GPM | 1.42 | 0.44 | 0.47 | 0.750 | 1908K | -08 SAE - 3/4-16 | -08 ORS - 13/16-16 | 8 GPM | 1.42 | 0.50 | 0.55 | 0.875 | 1910K | -10 SAE - 7/8-14 | -10 ORS - 1-14 | 12 GPM | 1.62 | 0.61 | 0.63 | 1.125 | 1912K | -12 SAE - 1 1/6-12 | -12 ORS - 1 3/16-12 | 30 GPM | 1.92 | 0.67 | 0.73 | 1.250 | 1916K | -16 SAE - 1 5/16-12 | -16 ORS - 1 7/16-12 | 40 GPM | 2.27 | 0.69 | 0.73 | 1.500 | 1920K | -20 SAE - 1 5/8-12 | -20 ORS - 1 11/16-12 | 50 GPM | 2.45 | 0.69 | 0.73 | 1.875 |

1904KView More

-04 SAE - 7/16-20

-04 ORS - 9/16-18

2 GPM

1.07

0.38

0.43

0.625

1906KView More

-06 SAE - 9/16-18

-06 ORS - 11/16-16

4 GPM

1.42

0.44

0.47

0.750

1908KView More

-08 SAE - 3/4-16

-08 ORS - 13/16-16

8 GPM

1.42

0.50

0.55

0.875

1910KView More

-10 SAE - 7/8-14

-10 ORS - 1-14

12 GPM

1.62

0.61

0.63

1.125

1912KView More

-12 SAE - 1 1/6-12

-12 ORS - 1 3/16-12

30 GPM

1.92

0.67

0.73

1.250

1916KView More

-16 SAE - 1 5/16-12

-16 ORS - 1 7/16-12

40 GPM

2.27

0.69

0.73

1.500

1920KView More

-20 SAE - 1 5/8-12

-20 ORS - 1 11/16-12

50 GPM

2.45

0.69

0.73

1.875

Page last updated: 6/16/20, 11:51 PM

This document, as well as all catalogs, price lists and information provided by Vonberg Valve, Inc., is intended to provide product information for further consideration by users having substantial technical expertise due to the variety of operating conditions and applications for these valves, the user, through its own analysis, testing and evaluation, is solely responsible for making the final selection of the products and ensuring that all safety, warning and performance requirements of the application or use are met.

The valves described herein, including without limitation, all component features, specifications, designs, pricing and availability, are subject to change at any time at the sole discretion of vonberg valve, inc. without prior notification.