Hydraulic Innovation

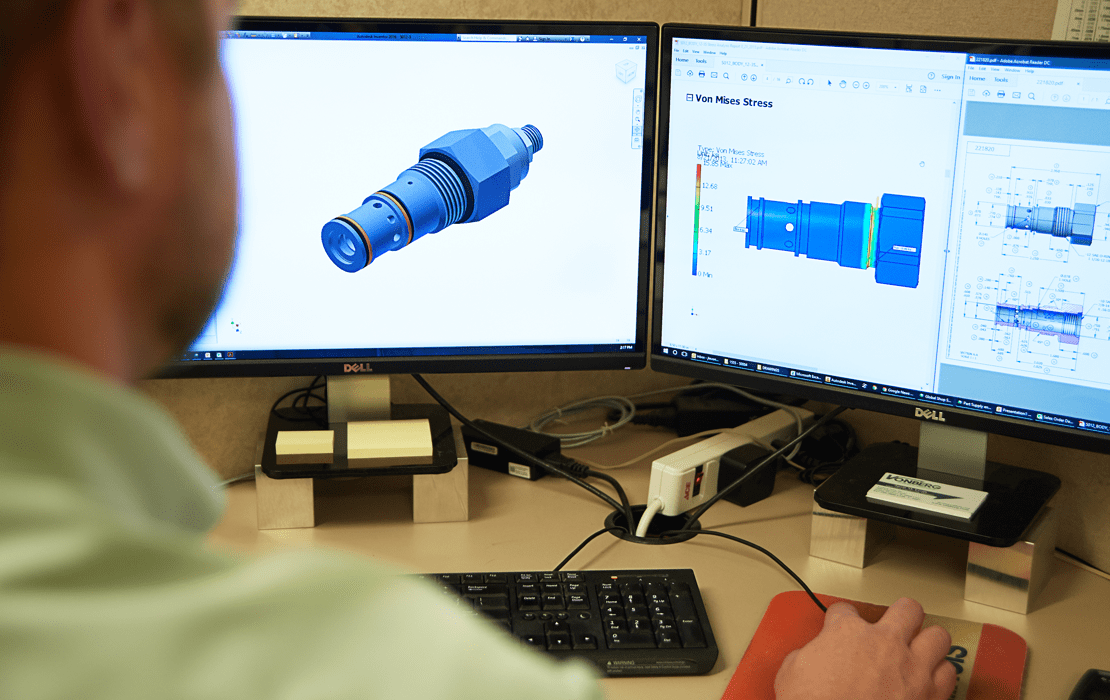

Design & Engineering

Our highly trained engineers have designed and developed an extensive hydraulic valve product line utilizing state of the art CAD Engineering Technology. When standard Vonberg products do not meet your specific requirements, our engineering staff can develop a custom solution to meet or exceed the demands of your application.

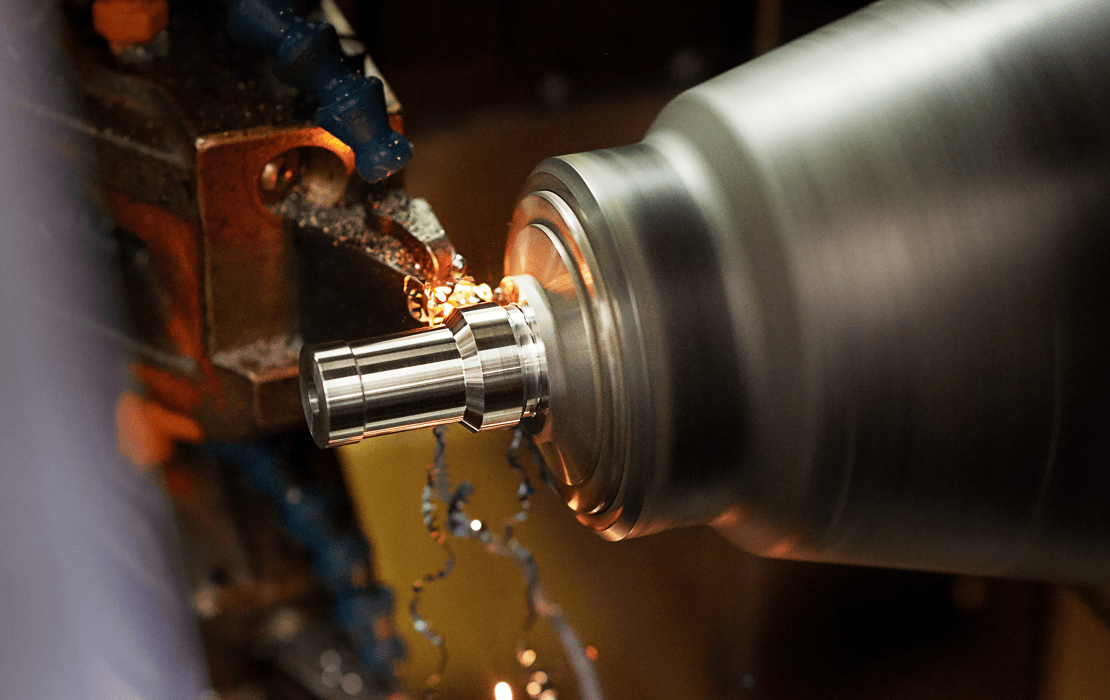

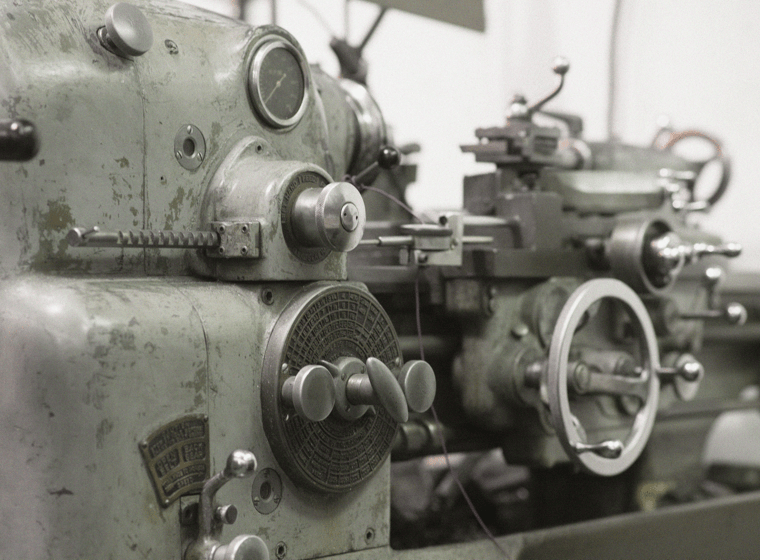

Manufacturing

Vonberg utilizes the latest in modern manufacturing technology, with automated CNC lathes and CNC machining centers maintaining the tightest tolerance possible, resulting in superior quality valve components. A fully integrated ERP system tracks all sales orders from entry, through manufacturing and production, until the moment the product ships, maintaining our reputation for providing the shortest lead times in the industry.

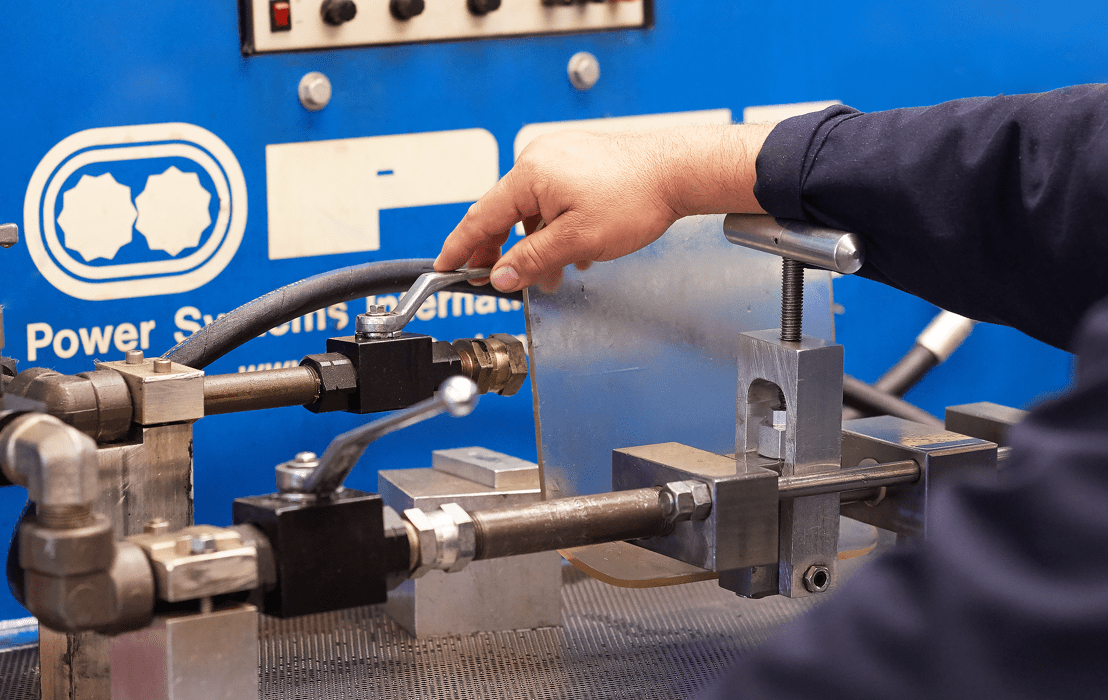

Assembly & Testing

The Vonberg assembly team combines highly skilled individuals with decades of knowledge and experience, allowing Vonberg to develop a reputation of unsurpassed quality in the hydraulic industry. All testing is done on high pressure test stands with specially designed fixtures to provide quick, accurate and reliable results. This unique test equipment allows Vonberg to analyze the product in a non-destructive manner and maintain the integrity of delicate pipe threads, o-ring connections and flare fittings.

Quality Assurance

Vonberg is ISO 9001 certified, and our quality assurance program emphasizes zero defects throughout manufacturing and production. The quality processes aid our highly trained workforce as they utilize calibrated instrumentation, specialized equipment, and documentation to form a superior quality system.

Our History

Established in 1971 by an industry veteran, Vonberg began offering innovative and proprietary solutions to the material handling industry. The development of the exclusive Surges Internally Dampened (S.I.D.) feature brought Vonberg flow regulators to the forefront of load lowering applications.

In 1990, Vonberg expanded the product line to include cartridge valves as a complement to the already established in-line valve offerings. These complementary lines developed and grew into the fully featured catalog of in-line, cartridge, and custom valves that Vonberg designs and manufactures for major producers of mobile and industrial hydraulic equipment. The product is sold nationally, and internationally, directly to OEM’s as well as through a networkof authorized distributors. Vonberg is an independent, non-union, family owned and operated company dedicated to timely delivery of innovative, competitively priced, quality products.

After the company’s early years in the city of Chicago, the facility and operations were relocated to the northwest suburb of Rolling Meadows, where, for 45 years, they expanded to support Vonberg’s growing product lines and new innovations. In May 2020, Vonberg relocated its operations to a newly renovated facility in the western suburb of Itasca, more than doubling its space and laying the foundation for further growth and development.