CHECK VALVE - POPPET

21

Directional Valves

1800 SERIES

CHECK VALVE - POPPET

CARTRIDGE •

STANDARD FLOW DIRECTION

Description

A CARTRIDGE STYLE, POPPET TYPE,

STANDARD FLOW CHECK VALVE INTENDED FOR BLOCKING FLUID FLOW.

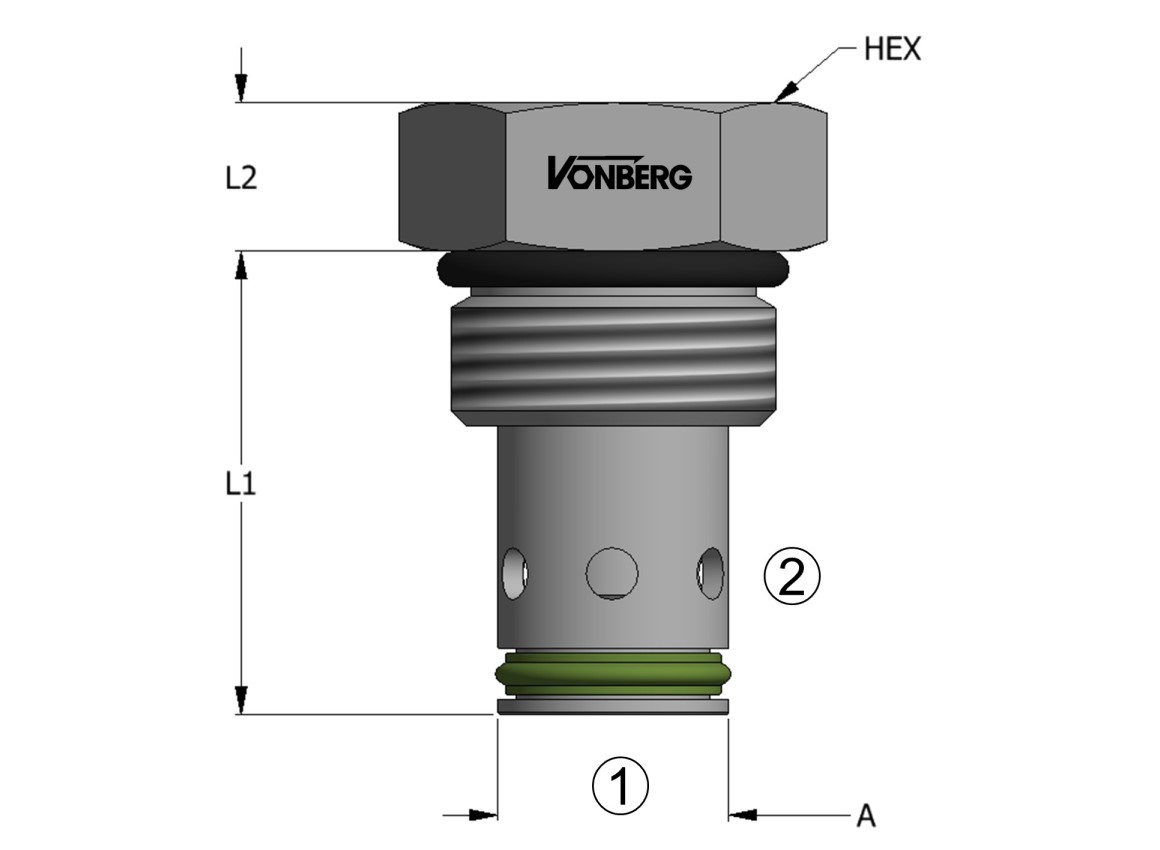

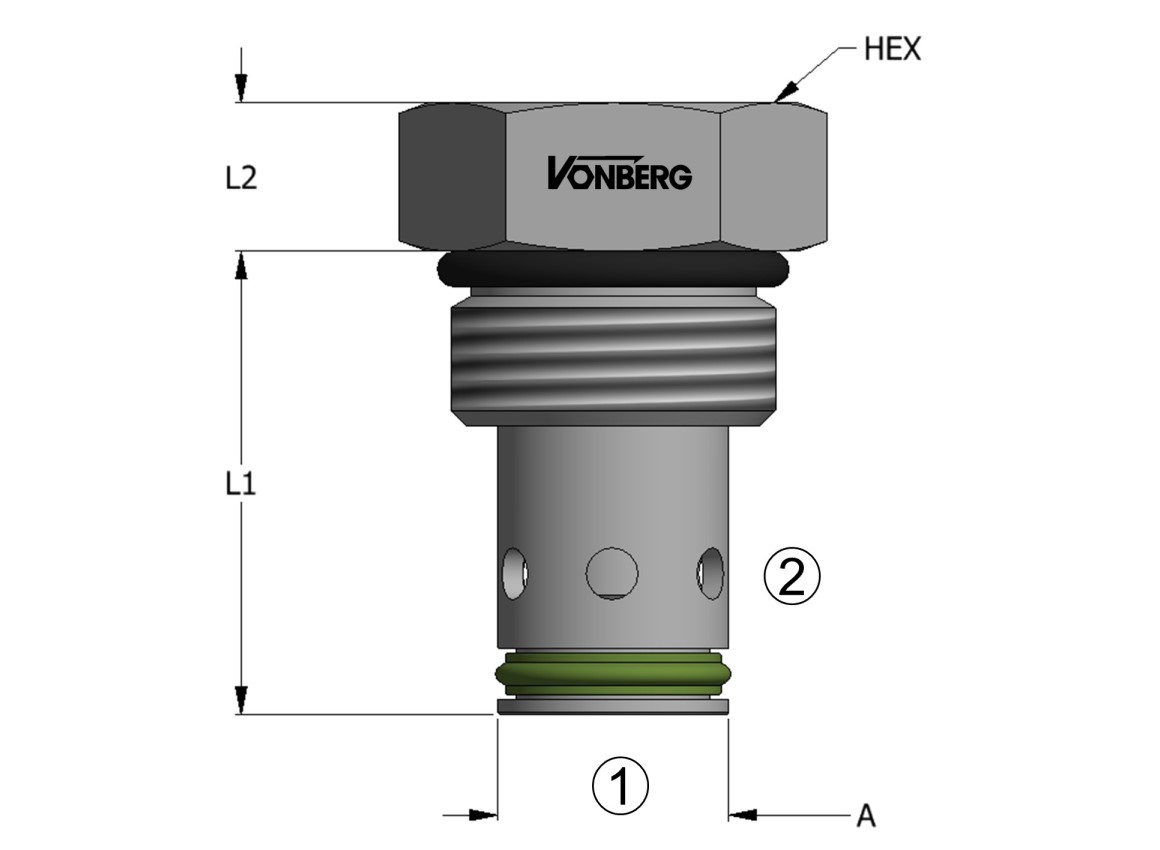

Product Rendering

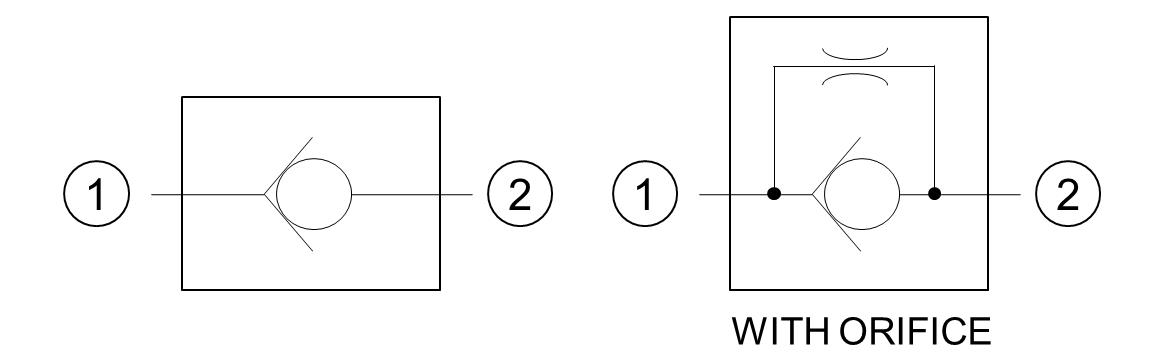

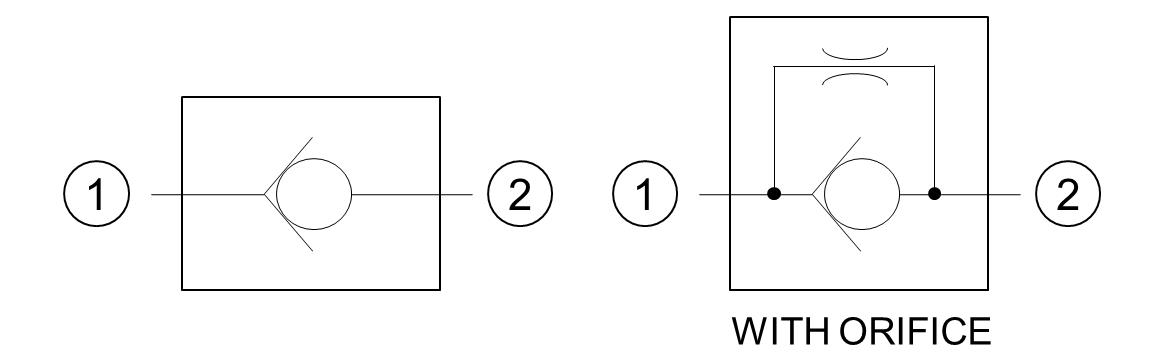

Schematic

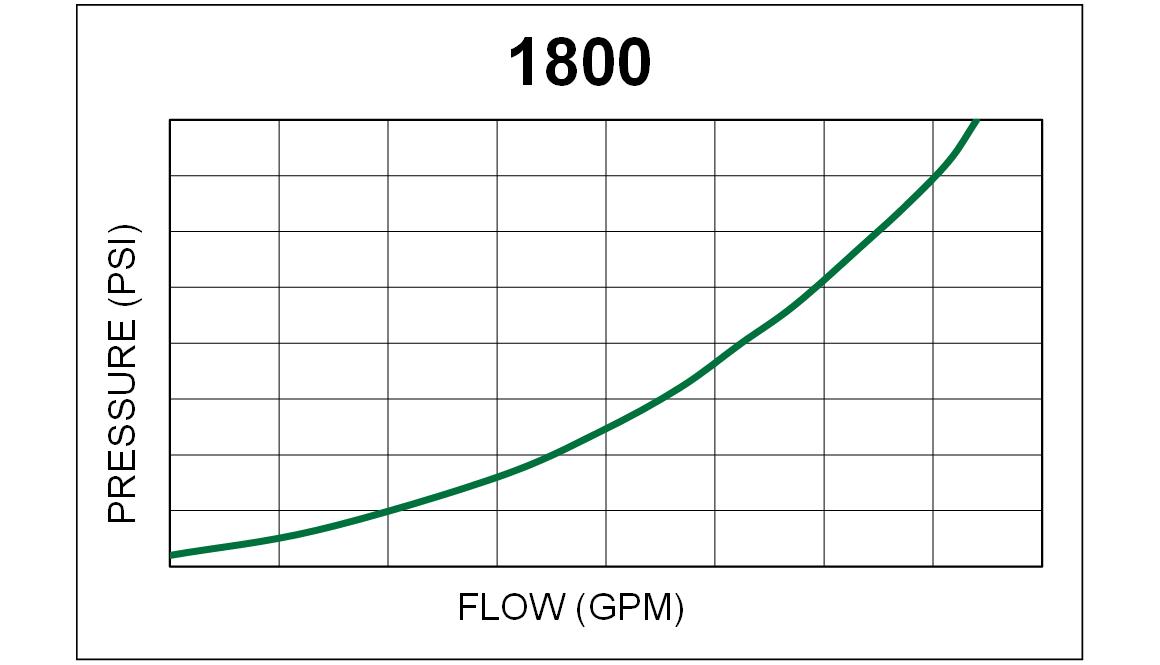

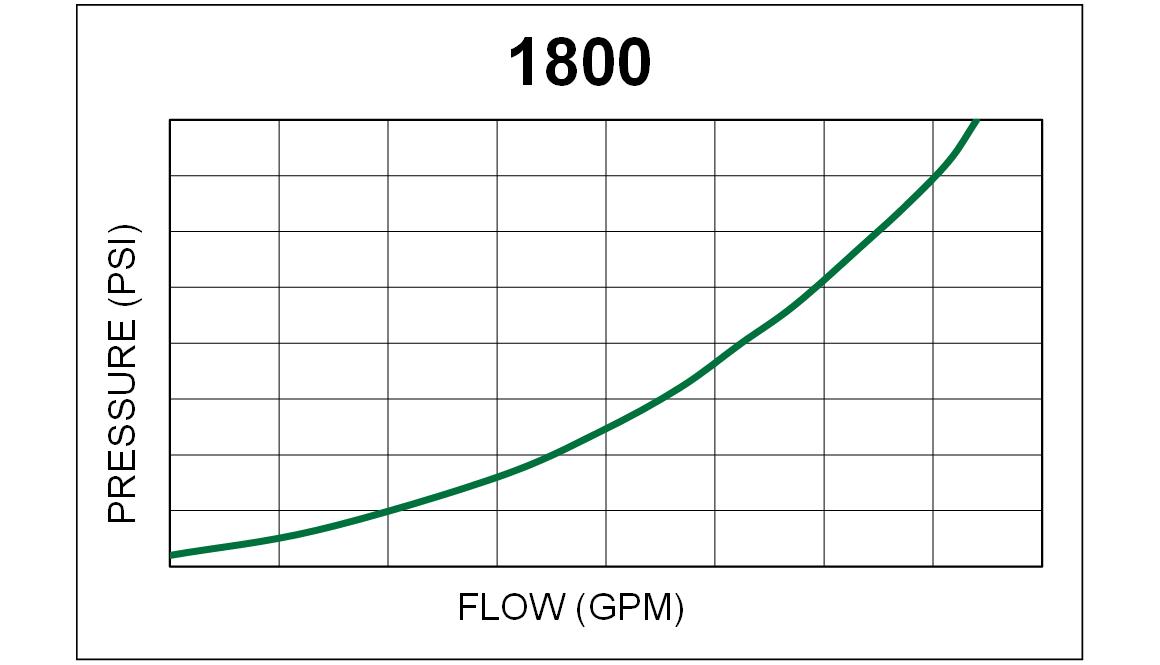

Typical Performance

Operation

- FLOW FROM (2) TO (1) IS BLOCKED WITH A SPRING BIAS TO ASSIST IN STATIC AND LOW LOAD CONDITIONS.

- FLOW FROM (1) TO (2) IS ALLOWED WITH A STANDARD CRACK PRESSURE OF 3-5 PSI.

Features

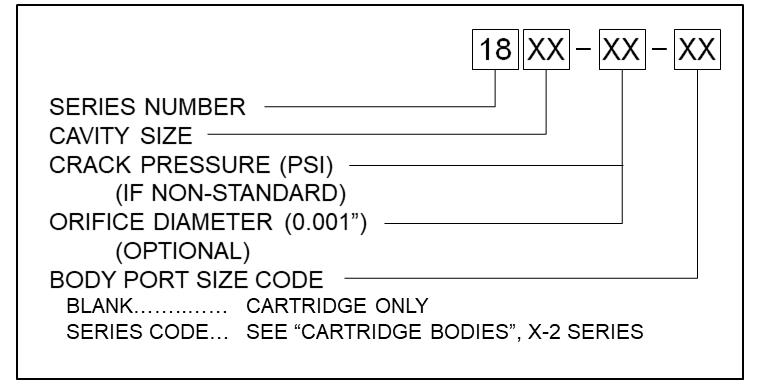

- SPECIAL CRACK PRESSURES AVAILABLE UPON REQUEST.

- INDUSTRY COMMON CAVITY

- LOW INTERNAL LEAKAGE, 5 DPM.

- STEEL BODY AND POPPET.

Specifications

| OPERATING PRESSURE |

5000 PSI |

| STANDARD CRACK PRESSURE |

3-5 PSI |

| TEMPERATURE RANGE |

250° F TO -40° F |

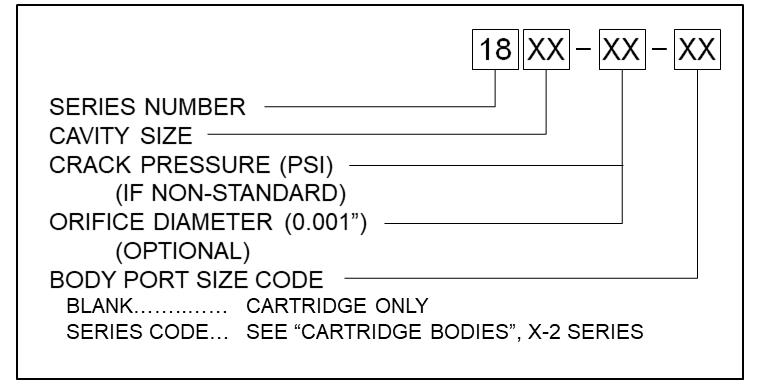

Ordering Information

| 1804 | 7/16 - 20 | 2.0 GPM | VC04-2 | 0.94 | 0.44 | 0.56 | 0.277 /

0.278 | 10 ft-lbs |

1806 | 9/16 - 18 | 4.0 GPM | FC06-2 | 0.84 | 0.26 | 0.69 | 0.467 /

0.468 | 15 ft-lbs | 1806L | 9/16 - 18 | 5.0 GPM | HVC06-2 & VC06-2 | 0.935 | 0.26 | 0.69 | 0.433 /

0.435 | 15 ft-lbs | 1808 | 3/4 - 16 | 6.0 GPM | VC08-2 | 1.10 | 0.36 | 0.88 | 0.495 /

0.497 | 20 ft-lbs | 1810 | 7/8 - 14 | 10.0 GPM | VC10-2 | 1.25 | 0.40 | 1.00 | 0.621 /

0.623 | 25 ft-lbs | 1812 | 1 1/16 - 12 | 20.0 GPM | VC12-2 | 1.81 | 0.49 | 1.25 | 0.870 /

0.873 | 40 ft-lbs | 1816 | 1 5/16 - 12 | 30.0 GPM | VC16-2 | 1.75 | 0.55 | 1.50 | 1.121 /

1.123 | 60 ft-lbs |

1804View More

7/16 - 20

2.0 GPM

VC04-2

0.94

0.44

0.56

0.277 / 0.278

10 ft-lbs

1806View More

9/16 - 18

4.0 GPM

FC06-2

0.84

0.26

0.69

0.467 / 0.468

15 ft-lbs

1806LView More

9/16 - 18

5.0 GPM

HVC06-2 & VC06-2

0.935

0.26

0.69

0.433 / 0.435

15 ft-lbs

1808View More

3/4 - 16

6.0 GPM

VC08-2

1.10

0.36

0.88

0.495 / 0.497

20 ft-lbs

1810View More

7/8 - 14

10.0 GPM

VC10-2

1.25

0.40

1.00

0.621 / 0.623

25 ft-lbs

1812View More

1 1/16 - 12

20.0 GPM

VC12-2

1.81

0.49

1.25

0.870 / 0.873

40 ft-lbs

1816View More

1 5/16 - 12

30.0 GPM

VC16-2

1.75

0.55

1.50

1.121 / 1.123

60 ft-lbs

Page last updated: 12/27/22, 8:20 PM

This document, as well as all catalogs, price lists and information provided by Vonberg Valve, Inc., is intended to provide product information for further consideration by users having substantial technical expertise due to the variety of operating conditions and applications for these valves, the user, through its own analysis, testing and evaluation, is solely responsible for making the final selection of the products and ensuring that all safety, warning and performance requirements of the application or use are met.

The valves described herein, including without limitation, all component features, specifications, designs, pricing and availability, are subject to change at any time at the sole discretion of vonberg valve, inc. without prior notification.